03 Nov Reimann GmbH with new laser cutting system and press brake

Mönchengladbach-based industrial manufacturer invests in machinery and expands range of services in the field of sheet metal processing

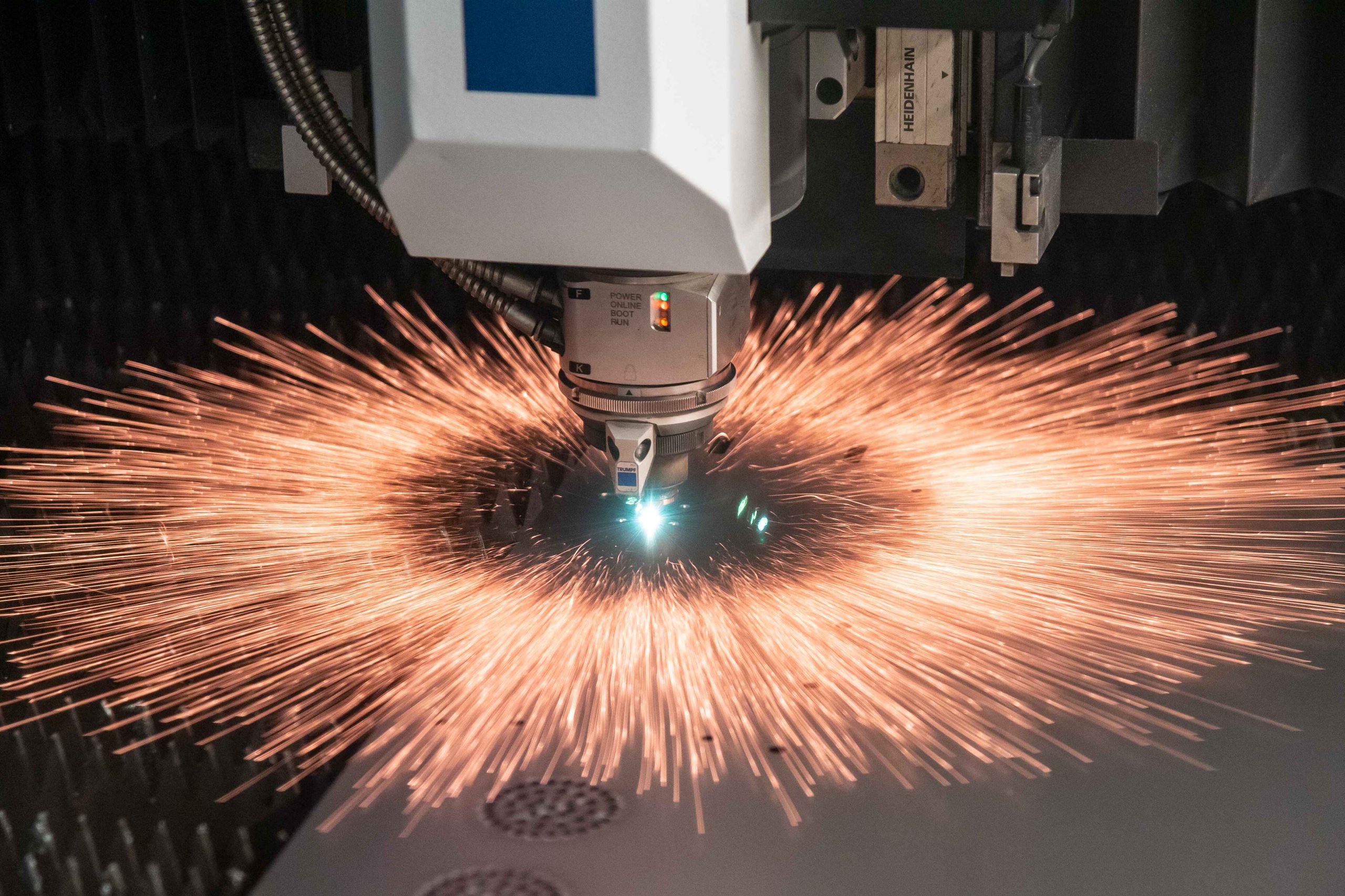

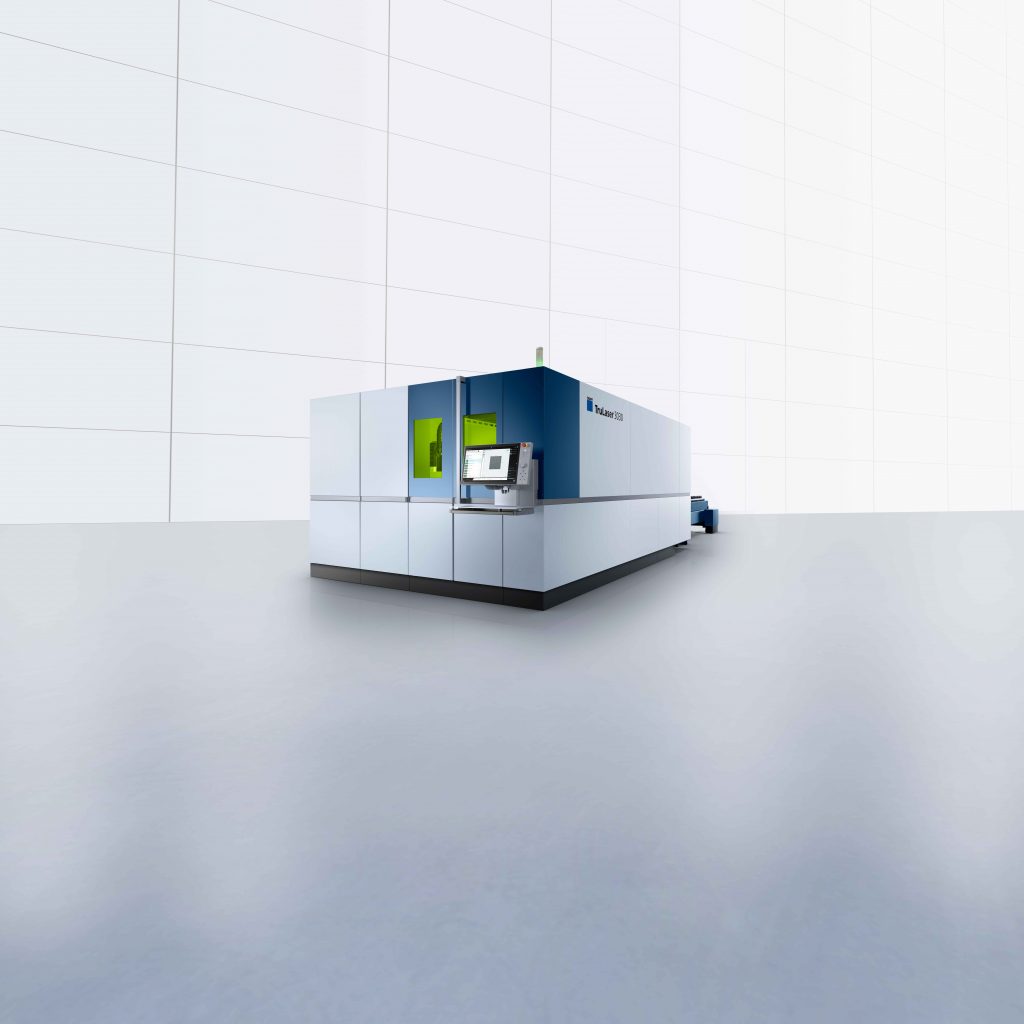

Mönchengladbach, Germany, Nov. 4, 2021 – Reimann GmbH has invested in a new TruLaser 3030 fiber laser cutting system and a new TruBend 5230 press brake from TRUMPF Machine Tools. The Gladbach-based company thus offers its customers an expanded spectrum within sheet metal processing and ensures optimization of the industrial manufacturer’s energy efficiency.

“We are proud to now be able to provide even more capacity for our customers with this investment,” says Jürgen Kreutzer, Managing Director of Reimann GmbH, welcoming the addition to the machine park. The new laser cutting system provides additional capacity, as the existing model is already fully utilized in an extended two-shift system.

Expanded range of sheet metal processing services from 2022 onwards

“The new laser cutting system works much faster and, above all, cleaner and delivers perfect cut edges. In addition, we can realize up to 70% cutting gas savings, so that we significantly improve our energy efficiency in terms of climate protection. From 2022 we will therefore be able to offer our customers an expanded range of services in the field of sheet metal processing. For our customers, this investment naturally also means a significant improvement in the quality of the end products,” Kreutzer continues.

The latest generation line is capable of processing large quantities of thick and thin sheet. An automatic die changer and an integrated automatic plate changer guarantee that the plates can be changed in a matter of seconds.

“With the additional investment in a laser cutting system, we are setting the course for further growth, as this will allow us to manufacture significantly more products ourselves and no longer have to outsource certain work,” explains Jürgen Kreutzer.

The course is set for further growth: new pressbrake complements investment

However, the laser cutting system is not the only investment at Reimann. A new press brake is also part of the expansion of the machine park in Mönchengladbach. “We want to continue setting trends in the industry in the future,” says Kreutzer, explaining his investment ¬decisions. “In addition to commitment and personal dedication, this also requires investment in our machines. That’s why we continuously keep our machinery up to date with the latest technology.“

Copyright image material in this press release: TRUMPF Group

About Reimann GmbH Reimann GmbH is an industrial manufacturer and, with its high-quality products, has been one of the most important suppliers for German and European mechanical and plant engineering for more than 45 years. With the claim “excellence in industrial solutions” the company combines the claim to be a competent and reliable partner for customers and to offer innovative solutions.

Under the leadership of owner and managing director Jürgen Kreutzer, Reimann has developed in just under 10 years from a steel fabricator to an industrial fabricator and specialist in the refurbishment of industrial furnaces. The family business takes on complex industrial projects in the business areas of industrial furnaces, technical insulation, stainless steel fabrication, boiler fabrication, pipeline construction, steel construction and sheet metal processing for national and international customers. In addition to on-site maintenance and assembly work, prefabrication in the company’s own production halls at its headquarters in Mönchengladbach is a core competence of Reimann GmbH.

Reimann GmbH’s customers include well-known companies and groups. For more information, visit www.reimann-gmbh.com.

Press contact Reimann GmbH Karin van Soest Telephone: 02161-8269743 – Mobil: 0172- 2524 845 – E-Mail: pressetelle@marvice.de