30 Jun Despite Corona: Reimann handles furnace refurbishment in record time

Complete refurbishment of two deep furnaces in only 6 months

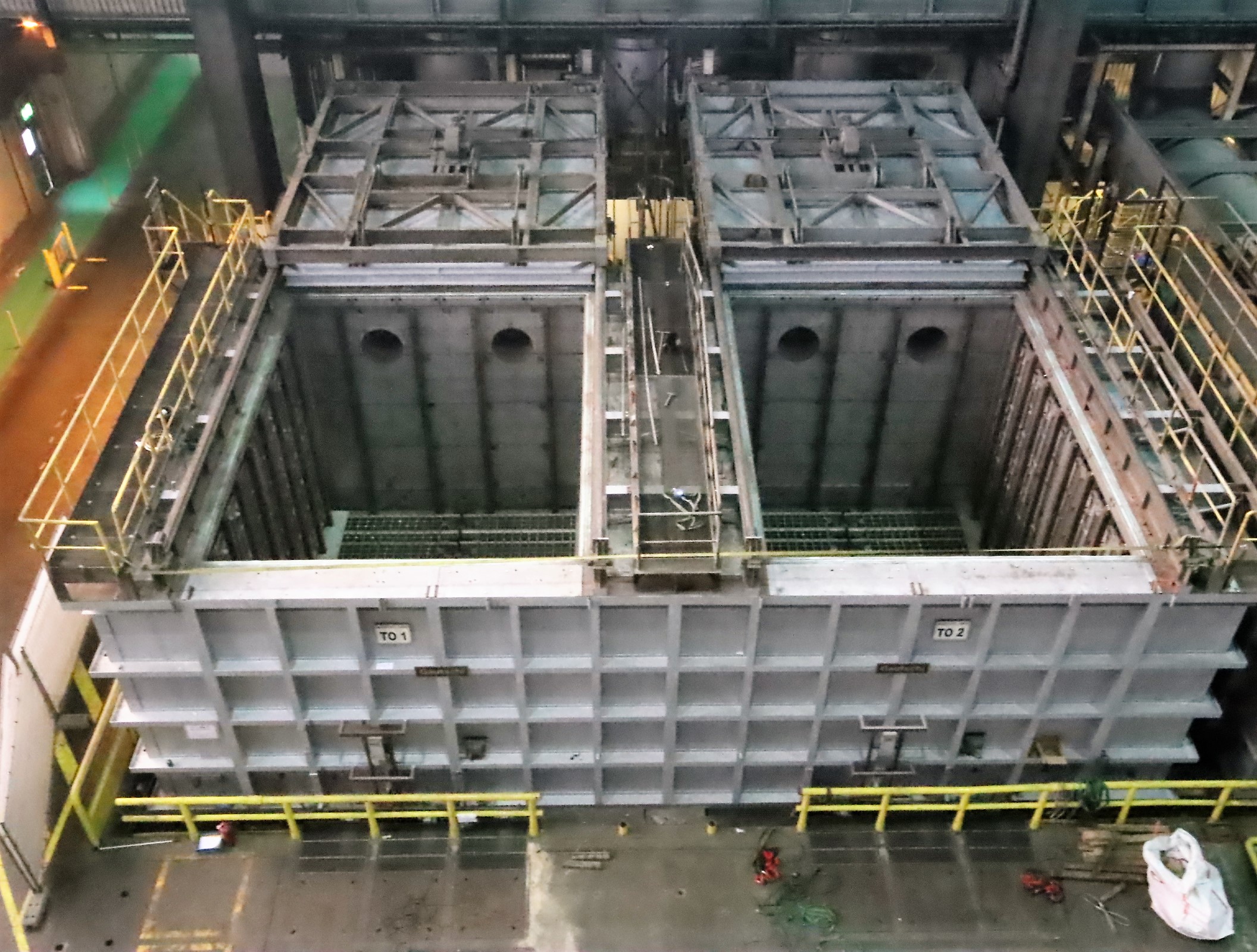

Mönchengladbach, 01.07.2021 – Special times – special challenges have to be mastered. Despite Corona, Reimann GmbH has refurbished a complete aluminum preheating furnace (deep furnace 1 and 2) for a Neuss-based company in a record time of only 6 months.

“We are particularly proud that, despite the Corona-related difficulties in material availability, we managed to completely refurbish the deep furnace within 6 months from receipt of the order, including partial construction, work preparation, fabrication, disassembly and assembly. Normally, we would calculate 10-12 months for a project of this size,” explains Jürgen Kreutzer, Managing Director of Reimann GmbH.

As part of the refurbishment, the project manager responsible for industrial furnace systems at Reimann, Mr. Christoph Apel, first drew up a refurbishment concept that included both the development of a new intermediate wall and other necessary refurbishment steps. “We first checked which parts specifically needed to be refurbished and then drew up a corresponding refurbishment concept,” describes Christoph Apel. Thus, the complete insulation of the furnace was replaced by a new insulation layer. The intermediate wall between the two furnaces was also replaced. In addition, the Reimann team also renewed the fan wheels, radiant tubes and the inner housing including the spiral housing in the furnace.

The Technical Managing Director of the company is satisfied with the progress of the project: “We have already been working very successfully with Reimann GmbH in the field of furnace refurbishment for several years. However, we have not yet had to plan any of the refurbishment projects under these special conditions. In this respect, it was also a really special project for us from start to finish. Because downtime for our industrial furnaces naturally also means that we have less capacity available for production. It is therefore all the more important that the downtimes are planned precisely and also adhered to. “

“All parts were manufactured on site in Mönchengladbach by Reimann and then assembled in the furnace,” explains Christoph Apel. “Over the project period, approximately 160 tons of partially heat-resistant material were processed for the new production, Apel explains. “

To illustrate the dimensions of such a project, one need only look at the dimensions of the aluminum preheating furnace produced: 16m wide, 8m deep and 8m high bear witness to the painstaking detail work required to assemble the approximately 10,000 individual parts.